frame

Добро пожаловать к нам!

Скорее присоединяйтесь к участникам форума нажав на одну из кнопок ниже!

Войти РегистрацияHelp with Little RP printer

Раздел: Общение и новости

Hi All,

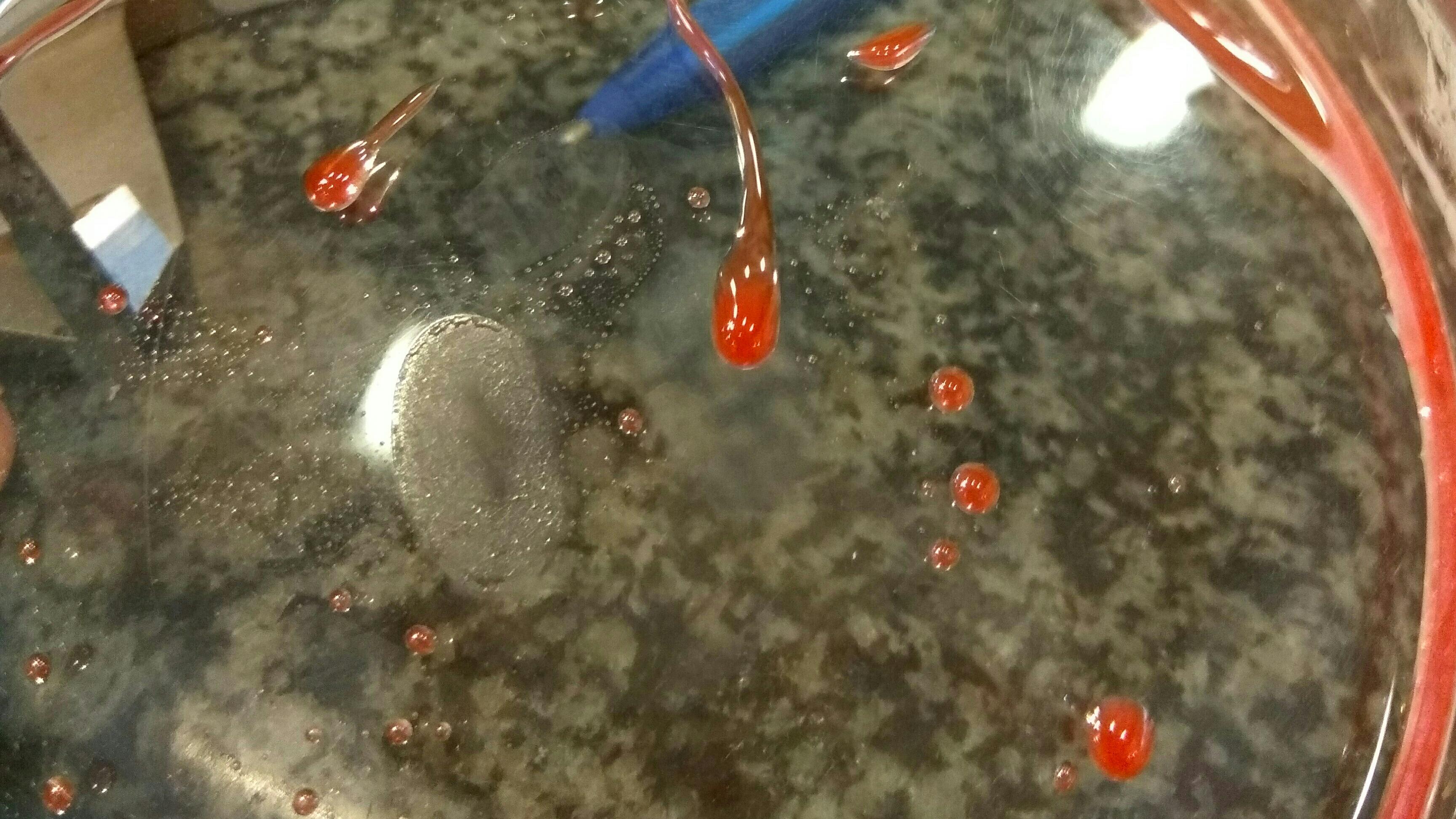

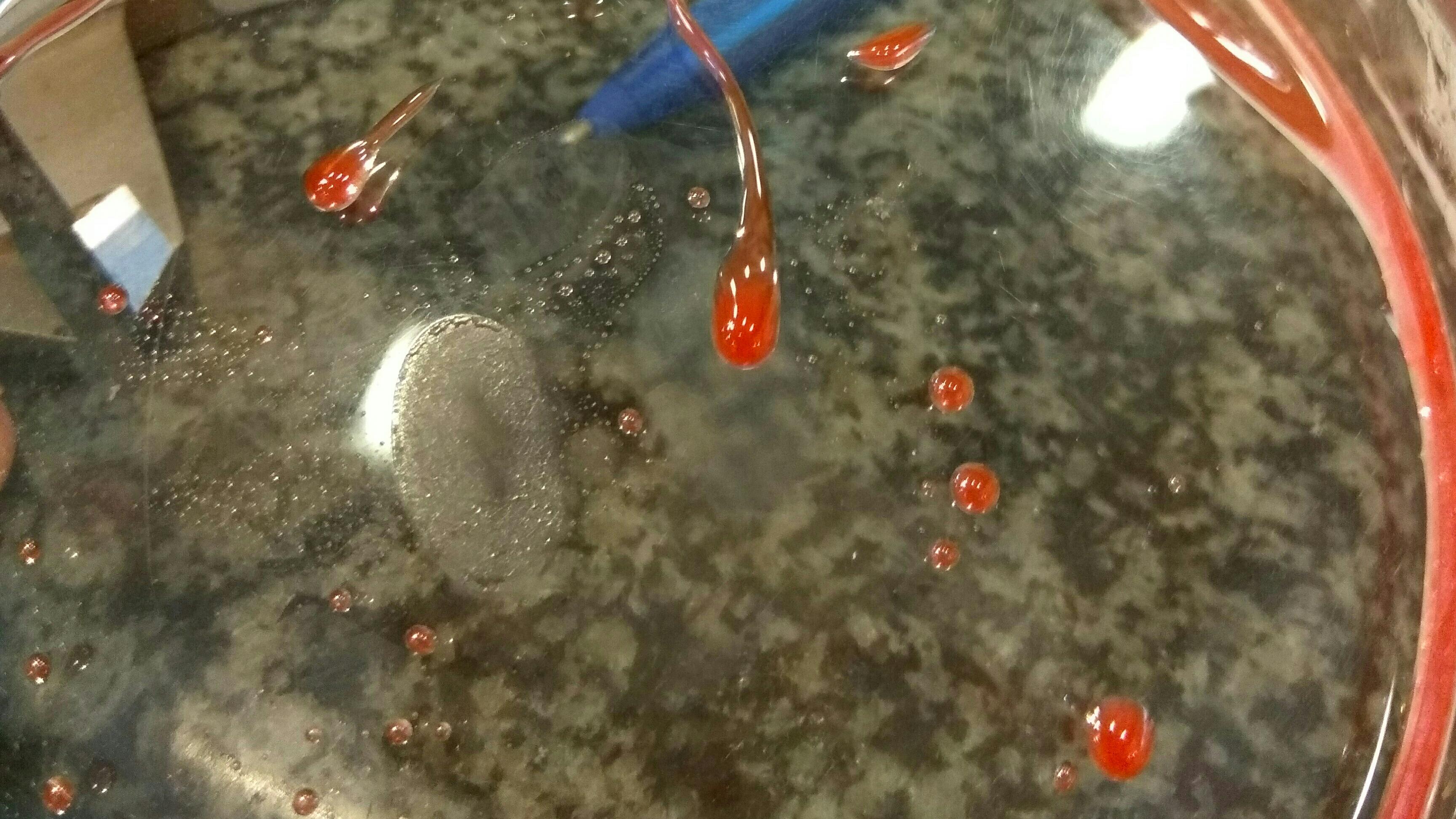

I have an issue with FDM everytime i print it fail as the FDM film break and the result is as the pics shown.

Anyone knows how to solve this problem?

Thank You

I have an issue with FDM everytime i print it fail as the FDM film break and the result is as the pics shown.

Anyone knows how to solve this problem?

Thank You

Войдите или Зарегистрируйтесь чтобы комментировать.

Комментарии

In further printing process the connection area is not so big and you need far less time for the curing. But remember that you will need the UV champer for to cure the models to the end aftes tha printing is finished. ok?

Look, can you maybe capture a video of how you work with your printer? It might be useful for me to help you.

Thank You

Thank You

Here My setting

2/ I dont see any speed settings for the first layers. Usially the moving speed is very low for them. That's to prevend damage of the PDMS. But anyways it's normal when it is sticking. I heard how my platform even quacks on the firt layers.

And what are the spots on the second video? Liquid drops?

In envisiontec machines it's much more parameters describing the movement of the parts. I

So according to what we have here I propose to low down the speed to minimum. Let's try to complete the first model